Digital product pass (DPP)

The EU wants to make it mandatory for all manufacturers by 2030.

We already have it in 2023. For good reason.

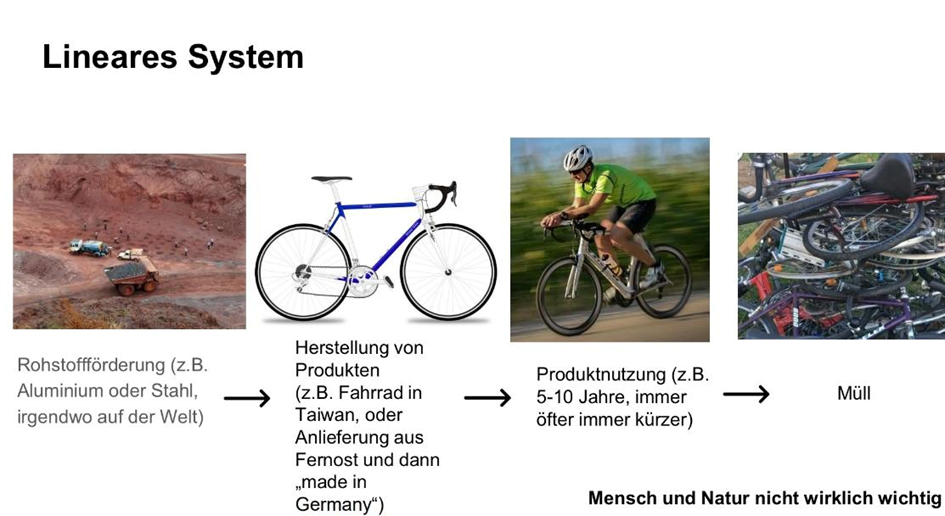

In the previous linear economic system there were the categories "new" and "used". When the warranty has expired, the manufacturer no longer has to worry about anything and can start preparing for the new sale. The end user is responsible for disposal. A product with low durability and poor repairability benefits the manufacturer.

The product design is created in such a way that there are incentives for a new purchase in the near future. The end consumer pays for a new product, complex service processes and prompt disposal.

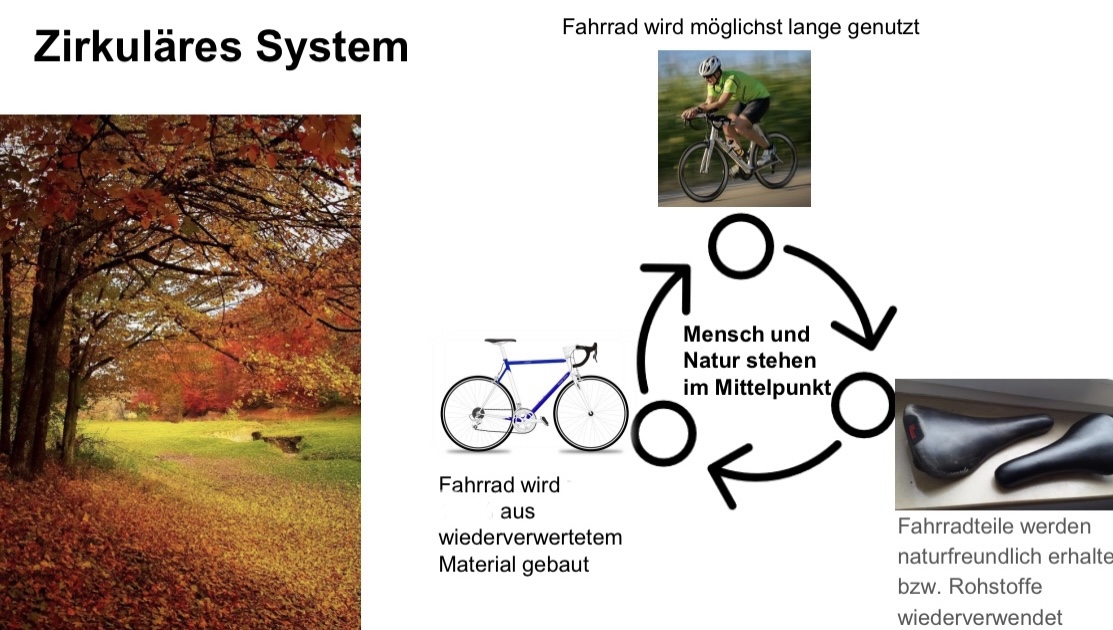

In the circular economy it all looks completely different. The previous categories no longer exist. There are working products that are in circulation. When a product stops working, it is repaired, refurbished or remanufactured. When individual parts are no longer usable, they are replaced and recycled. In turn, functional units come from recycling, which are then reinstalled. No matter where you start, everything takes place in cycles over longer periods of time.

The product design is such that it lasts a long time, is easy to repair and can be flexibly reacted to changing needs. The end user pays for the smoothest possible use.

Since the goal is for the product to function continuously and over a long period of time, documentation that is as complete as possible makes sense. The bike is built, it is repaired by different mechanics or by the user himself, parts are exchanged, and the bike is eventually disassembled and refurbished by the manufacturer. All these processes are recorded in the digital product pass.

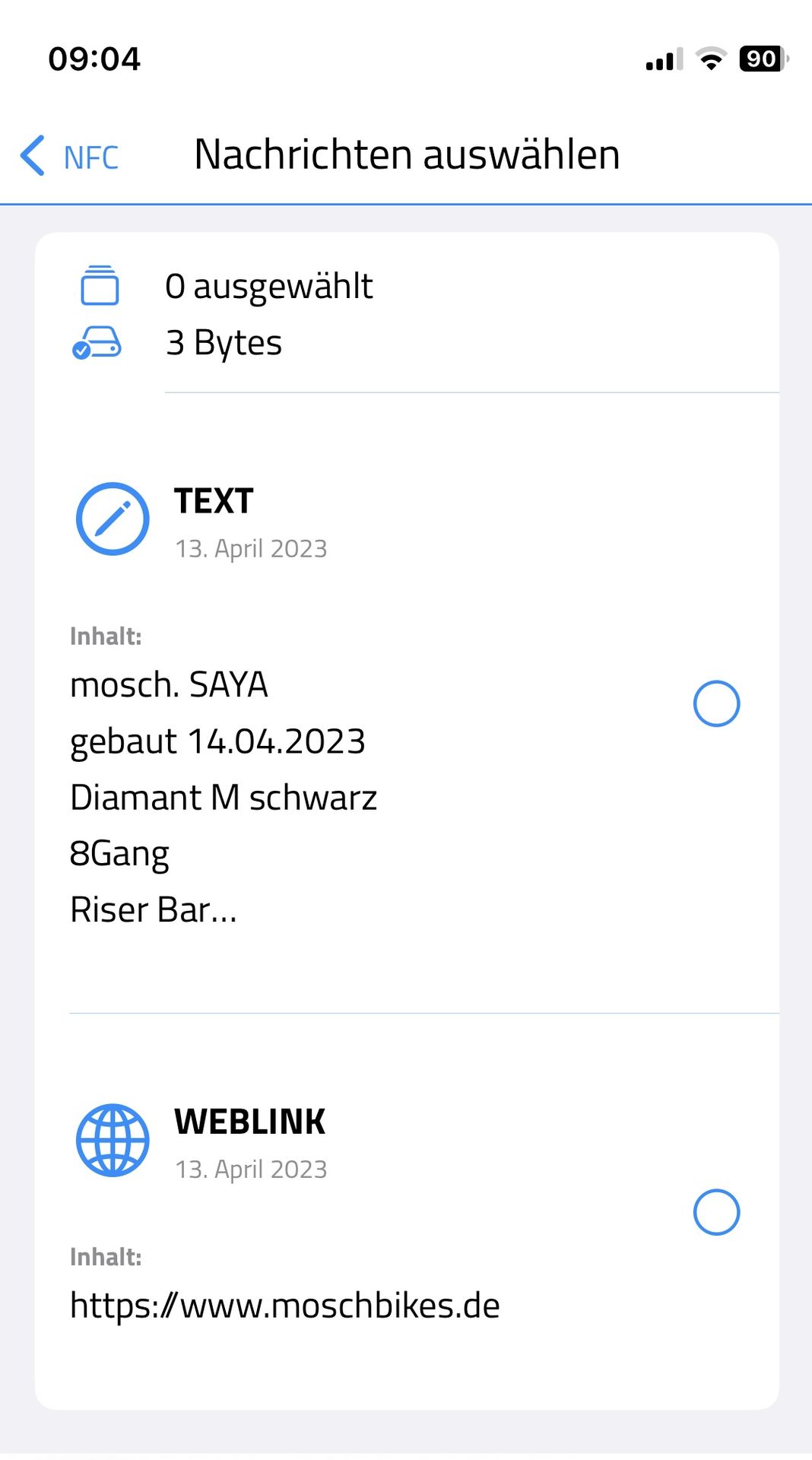

The digital product pass from mosch. is something like the life book of the bicycle. It is located on an NFC tag on the left side of the bottom bracket ("red dot").

The digital product pass from mosch. is something like the life book of the bicycle. We are at the beginning of an exciting journey and first have to find out which aspects are particularly important. Here we are dependent on feedback from practice. That is how it goes:

1. Load an app on your phone that can read and write NFC tags.

2. Hold your phone close to the NFC tag and find out what the history of your bike is like.

3. Add if you make a change, e.g. change a shifter cable, ideally with date, place and name/acronym.

4. Ask external mechanics to add the work they have done.

5. Do not delete anything and only write in meaningful processes. It is an open system that works on the basis of trust.

6. Let us know if you have an idea or there are problems.